When you develop or design engineer a new thermoplastic part, speed and cost-efficiency are critical during the entire product development process. In order to avoid mistakes after invested in expensive mass production molds short run or prototype moulds can be made.

A second reason to opt for short run molds is that final products is exclusive and only made in small quantities.

At our company Triple-c Injection Molds China, we specialize besides mass injection molding in short-run injection mold solutions for volumes between 100 (hundred) to 2,000 shots. Choosing the right mold material ensures your project stays on time and within budget.

the top 5 materials for low volume molds

1. Aluminum (6061 / 7075)

- Fast to machine, lightweight, and ideal for rapid prototyping

- Best suited for non-abrasive materials and simple geometries

- Typical lifespan: up to 2,000 shots

2. P20 Tool Steel

- Offers greater durability than aluminum while still cost-effective

- Ideal for textured surfaces and more complex designs

- Suitable for 5,000+ cycles in many cases

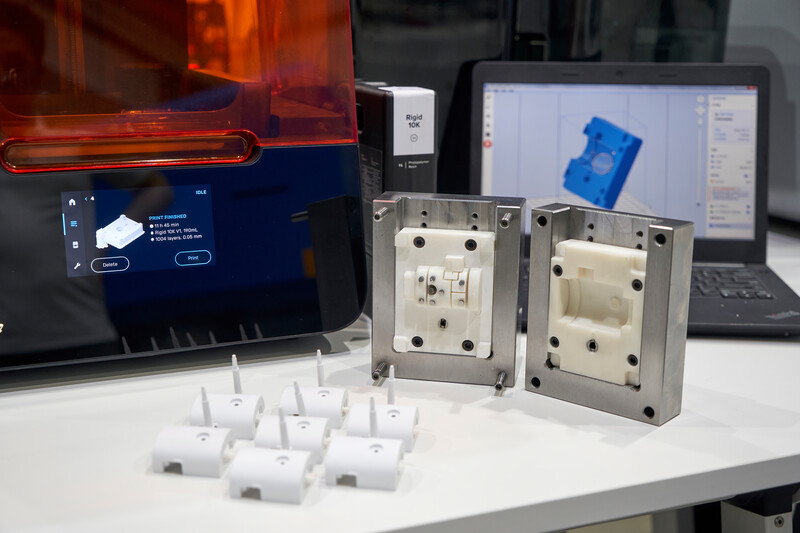

3. 3D Printed Tooling

- Rapid turnaround, especially for concept testing

- Best for simple shapes and low-temp plastics

- Typical lifespan: 100–500 shots

4. Epoxy or Urethane Mold Systems

- Extremely low cost and fast fabrication

- Suitable for early-stage testing or display models

- Lifespan: typically under 200 shots

5. Hybrid Aluminum-Steel Molds

- Combine aluminum bases with steel inserts in wear areas

- Great for glass-filled plastics or tight tolerances

🔸 How to Choose?

Choosing the best mold material depends on:

- The total Shot quantity of your part that is required

- Plastic resin used (e.g., PP, ABS, GF-Nylon)

- Part complexity and finish

- Lead time requirements

Our tooling engineer experts can help you evaluate the best option for your application.